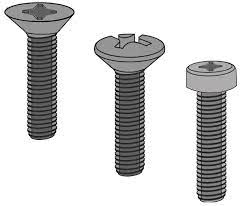

Introduction: cross recessed machine screw, also known as Phillips screws, are among the most common types of screws used in various applications. These screws offer a straightforward and effective way to secure components, but there is more to them than meets the eye. In this comprehensive guide, we’ll explore everything you need to know about cross recessed machine screws, from their history to their applications and common FAQs.

The History of the Cross Recessed Machine Screw

- Origins of the Phillips Screw

- Impact on Modern Fastening

Types of Cross Recessed Machine Screws

- Phillips Head

- Pozidriv Head

- JIS Cross Head

- Frearson/Reed & Prince

Advantages of Cross Recessed Machine Screws

- Self-Centering

- Reduced Slippage

- High Torque Transfer

- Mass Production

Applications of Cross Recessed Machine Screws

- Woodworking

- Electronics

- Automotive Industry

- General Construction

FAQ Section:

Q1: Who Invented the Cross Recessed Machine Screw?

A: The cross recessed machine screw was invented by Henry F. Phillips in the 1930s. His invention revolutionized the fastening industry by making screws easier to use and more reliable.

Q2: What’s the Difference Between Phillips and Pozidriv Screws?

A: While both have cross-shaped recesses, Pozidriv screws have additional flanks, allowing for better torque transfer and reduced cam-out compared to standard Phillips screws.

Q3: When Should I Use Cross Recessed Machine Screws in Woodworking?

A: Cross recessed machine screws are excellent for woodworking due to their self-centering design. They help prevent wood splitting and ensure a secure, flush fit.

Q4: Are There Special Screwdrivers for Cross Recessed Screws?

A: Yes, you should use the appropriate screwdriver with the correct size and shape for cross recessed screws. Using the wrong driver can damage the screw heads.

Q5: Can Cross Recessed Machine Screws Be Used in Wet Environments?

A: It’s essential to choose the right material and coating for cross recessed machine screws if you plan to use them in wet or corrosive environments. Stainless steel or plated screws are often suitable.

Q6: Can I Use Cross Recessed Screws for Electronics and Precision Work?

A: Yes, cross recessed screws are commonly used in electronics due to their self-centering and secure fastening properties. Precision screwdrivers are often used for such applications.

Q7: Are There Cross Recessed Screws with Different Head Styles?

A: Yes, cross recessed screws come in various head styles, including flat heads, pan heads, and round heads. The choice depends on the specific application and aesthetics.

Conclusion:

Cross recessed machine screws have a long history and continue to be a popular choice for fastening components in various industries. Their self-centering design, torque transfer efficiency, and versatility make them an invaluable part of our daily lives. Whether you’re a DIY enthusiast or a professional tradesperson, understanding the different types, applications, and advantages of cross recessed machine screws can help you choose the right screw for the job.